| Contaminant |

Maximum Concentration Allowed |

Actual Concentration ** |

| Particulates (PM10) |

50 micrograms per cubic meter (μg/m3) |

25 μg/m3 to 34 μg/m3 |

| Formaldehyde |

50 parts per billion (ppb) |

7 ppb to 11 ppb |

| Total volatile organic compounds (TVOCs) |

500 micrograms per cubic meter (μg/m3) |

< 140 μg/m3 in all locations (below low limit of detection) |

| Carbon monoxide (CO) |

9 part per million (ppm) and no greater than 2 parts per million above outdoor levels |

0.6 ppm to 1.1 ppm |

| 4-Phenylcyclohexene (4-PCH)* |

6.5 micrograms per cubic meter (μg/m3) |

N/A |

* This test is only required if carpets and fabrics with styrene butadiene rubeer (SBR) latex backing are installed as part of the base building systems.

Since the carpets and fabrics used in the building did not contain SBR the 4-PCH testing was not required.

** Measurements were taken from 5 different interior locations within the building on October 9, 2012. |

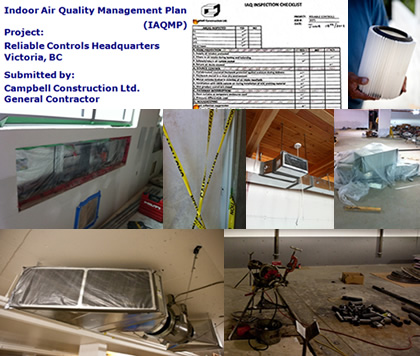

During Construction

During Construction